RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

A single source provider of flexible packaging and rigid tray packaging solutions, ProMach serves a variety of industries and applications. With numerous machinery installations worldwide and a vast portfolio of rugged and proven solutions, ProMach offers extensive experience handling a wide range of products in diverse conditions. ProMach consults with customers to identify the ideal package type to fit their unique application for each project, giving customers both choice and flexibility. Many of the world’s most successful brands use ProMach solutions to package their products into bags, pouches, sachets, stickpacks, trays, and more.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreFeatures & Benefits

- Small footprint

- Unwind system with integrated auto-alignment

- Splicing table

- Film compensator

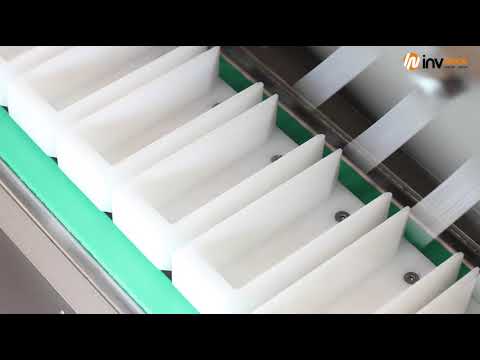

- Adjustable vertical cutting blades

- Powerful horizontal sealer

- Powder fillers assembled in a mobile platform for cleaning

- Touch screen panel

- PLC control

- Can package liquid, pasty, granulated, powder, or solid products

- Non-bulky package varies depending on customer needs and we can offer

- Duplex format with perforations

- Twin, contains two different products

- Sugar and stick, with different fillers, solid and granulate

Options

- Integrated coding systems (Laser, Inkjet, TTO)

- Tear notch

- Gas flush

- Vacuum assist

- Diamond seal end-cut

Stickpack Styles

SP6

SP9

SP12